Corporate Information

Grinding principles and usage of VSI sand maker

3/26/2012 6:56:06 PM

VSI sand maker (vertical shaft impact crusher) is the type of fine grinder which is used a free impact of material particles with a wear plate. Any hard or friable materials can be ground with low value of metal waste. This type of mill is combined with a classifier for fine tuning of a product size.

Grinding principle

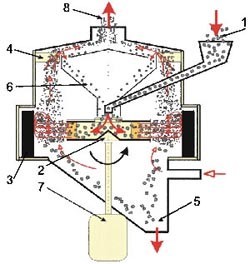

A schematic drawing of a VSI sand maker is shown at Fig. 1. Raw material particles transports via hopper (1) into the accelerator (2). An accelerator (2) rotates with a high speed and particles increase their speed by a centrifugal force. After leaving channels of the accelerator particles impact with a wear plate (3) in the grinding chamber. A high speed impact leads to destruction of particles into pieces of different size. Big particles (greater than 1 mm) fall down to outlet (5) and later they transport to hopper by an elevator. Other particles (less than 1 mm) lift by air stream into a classifier where blades (4) make rotating dust flow. Middle size particles shift to wall by centrifugal force in a big chamber of a classifier and fall down to cone (6) and later they move into an accelerator (2). Small particles move by air stream to outlet (8). Fine tune of a product size is achieved by changing of blade angle.

Fig. 1. A schematic drawing of a VSI sand maker

Usage of VSI sand makers

You cannot use VSI sand maker 'as is'. We need to organize feeding, an air stream and its cleaning from product (dust). Therefor full complete grinding line consists of a feeder, an elevator, a VSI sand maker with an air classifier, a cyclone, a fan and a bag filter. If raw material is soggy we need to organize drying before grinding.gy consumption.